Roter Dryer

Rotary dryer: This machine is one of the types of industrial dryers that are used to dry granular and powdery materials in high tonnages.

Rotary dryer

Rotary dryer is another name for rotating dryer.Rotary dryers are used to dry various powders in the chemical, food, mineral and sanitary industries.

The operation of this rotary dryer is circular and with spiral movement and due to the flow of hot air, the moisture of the product is lost by the device and finally the dried product is discharged from the outlet of the device.

The heat created inside the rotary dryer dries the products in two direct and indirect ways

Direct method:

By using the fuel consumed

by the rotary dryer (diesel, coal, gas, diesel, electricity) which is designed

and produced based on the needs and orders of the customer, the required heat

of the device is produced.

Directing the heat to the

products in the rotary device is that the heat created in the furnace is

directed into the drum with the help of fans and it will dry the powdered or

granular materials.

Indirect method:

In the indirect method,

hot air is not in direct contact with the materials inside the drum, and the

products lose their moisture through the passage of hot gas or condensation of

water vapor from the pipes located on the inner surface of the drum.

Advantages of rotary dryer

Low maintenance cost; so it is economical.

It has the largest capacity compared to any type of dryer.

Rotary dryers are less sensitive to particle size.

It can accept the highest exhaust gases of any type of dryer.

Disadvantages of rotary dryer

A relatively long residence time causes dispersion by moving the material along the drum It can be designed for open circuit, partial gas recycling and SSD designed. Excessive void losses in

the existing gas stream are possible, especially if the material contains very

fine particles due to the large gas volume and high gas velocities typically

required.A robust structure with

various lifting options can be concurrent or countercurrent allows the use of higher drying temperatures

Application of rotary dryer Salimi Azar

- Drying all kinds of vegetable and fruit wastes (beet waste, vegetable waste, sugarcane waste)

- To dry the waste of slaughterhouses and animal intestines for the production of fish food, pets, poultry feed and agricultural fertilizer.

- In the chemical industry for drying iron sulfate, manganese carbonate, zinc carbonate…

In asphalt production, a rotary dryer is used to dry and heat the sand in the asphalt

How the Salimi Azar rotary dryer works

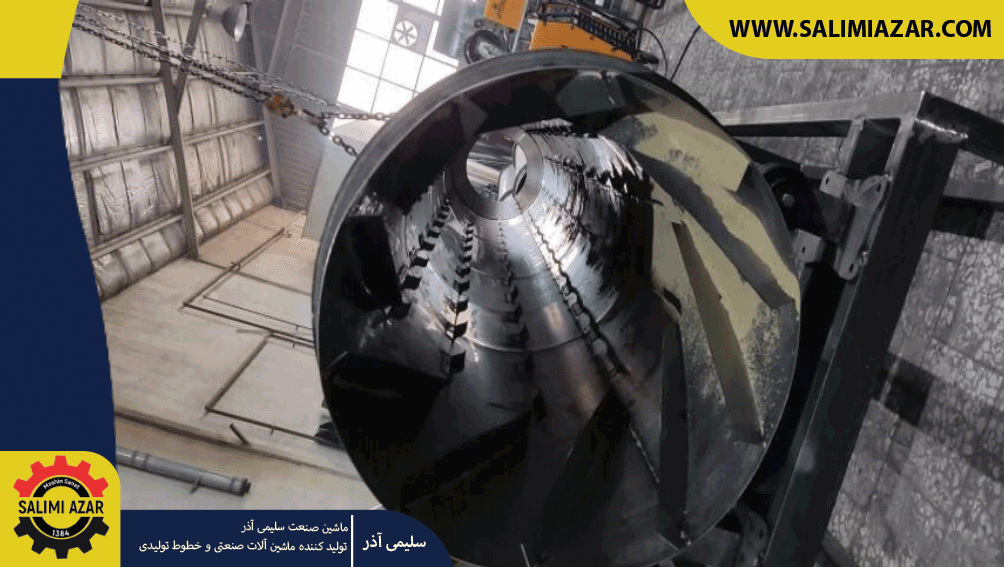

The rotary dryer consists of several main parts, including (drum, furnace for heat generation, tank for feeding (input of materials into the drum) and intelligent controller (PLC)).

The rotary dryer has a cylindrical chamber (drum) in which the product enters from one side and exits from the other side after drying. At first, the product is stored in a tank and gradually enters the drum with the hopper system.

The cylinder rotates with the help of a powerful gear motor. Due to the inclination of the cylinder (0 to 15 degrees) and with the help of the spiral blades in the inner wall, the product is directed forward in addition to turning upside down. Meanwhile, powerful fans blow the heat generated by the heat source into the cylinder and dry the product.

The moisture removed from the product is removed by the suction of the centrifugal fans and through the channels installed in different parts of the device. Finally, the dried material is gradually removed from the other side of the drum. The rotary dryer of Salimi Azar is smart and all the mentioned steps are performed automatically with the settings entered in the machine’s PLC.

Table of Roter Dryer information

( Salimi Azar )

| price | Dehumidification Hours/ton | power transfer | thickness | pipe length | diameter | gearbox | dynamo | Device Type | R |

| _ | 7%/1t | ring | 2 mm | 5000mm | 500mm | 60mm | 4 kw | Roter dryer | 1 |

| _ | 10%/1t | ring | 3mm | 6000mm | 700mm | 75mm | 5.5kw | Roter dryer | 2 |

| _ | 13%/1t | gear | 3mm | 7000mm | 900mm | 75mm | 7.5kw | Roter dryer | 3 |

| _ | 17%/1t | gear | 4mm | 8000mm | 1100mm | 90mm | 7.5kw | Roter dryer | 4 |

| _ | 25%/1t | gear | 5mm | 9000mm | 1250mm | 90mm | 11kw | Roter dryer | 5 |

| _ | 35%/1t | gear | 6mm | 10000mm | 1400mm | 100mm | 11kw | Roter dryer | 6 |

| _ | 50%/1t | gear | 8mm | 12000mm | 1550mm | 100mm | 15kw | Roter dryer | 7 |

| _ | 65%/1t | gear | 8mm | 15000mm | 1550mm | 100mm | 15kw | Roter dryer | 8 |

Types of rotary dryers:

1-Single wall rotary dryer

2-Double wall rotary dryer equipped with cooling and heating system

3-Stainless steel / iron

4-Anti-acid 316 stainless steel

5- Do not use 304 stainless steel