Salimi Azar industrial machine

- Industrial conveyor belt

- Detergent powder production line

- Packaging filling machine

- Horizontal industrial mixer

Raw materials of light washing powder production line

alkaline liquids (caustic soda)

Sodium silicate 30-55%

caustic soda 30-40%

Glauber’s zeolite and salt

Sulphonic acid

65 to 70% water

Sodium silicate

Sodium carbonate

Pentazodium

Product production process

in the light detergent production line

In the slurry preparation unit, which depends on different combinations of detergents, all kinds of liquid and solid materials are heated and these solids turn into liquid. With slow shaking, they enter the tank and this action makes the material stable and uniform. Then, by the frame mixer pump and the weight sensor, the dose of each material entering the mixer tank is controlled. The slurry is ground at high speed in the tank and filtered by the homogenizing mill. Then, after passing through the high pressure pump, the slurry is transferred to the spray gun at the top of the spray tower and is molded after cleaning and drying.

The hot air source of the device can be supplied with natural gas, oil fuel or burnt coal. The main equipment at this stage is: (stove, heater and burner group), the structure of each of which is different. In the next step, the slurry is homogenized at the top of the tower by the spray dryer, which is in the form of a conical pulverizer column, and the hot air moves uniformly from the tube into the annular tube from the bottom and transfers the heat. After that, they dry and form a hollow granular washing powder. Inside the powder column, there is a device for sweeping, which can clean the powder stuck to the column wall in a rotating manner. Then the produced material is removed by the conveyor belt and transferred to the air cooling unit and tail gas for wastewater treatment.

The temperature of the detergent is much higher than the cooling tower and needs to be cooled. At this stage, the detergent is cooled by the air cooler and separated from the air by the solution separator in the upper part, and then the air goes to the exhaust of the purification unit. The gas is transferred. In the wastewater treatment unit of the washing powder production line, the exhaust gas from the top of the powder tower and the solution separator enters the wastewater treatment.

In the next step, some components in detergents have a high temperature. Therefore, all kinds of enzymes and other solid raw materials such as soda ash are continuously entered into the mixer by belt scales with the formula, and then the base powder and all other materials are uniformly mixed and transferred to the packing room. In the final packaging stage of the product, detergents are transferred to plastic bags using a semi-automatic gravity method. In the stage of transportation and storage of raw materials, water, electricity and current are needed, which have configurations are different

Product features

These powders are much cheaper than other detergents.

Powders are more durable than liquids and can be stored.

Consumable parts of the washing powder production line

Engine valves

Liquid purification equipment

Wire brush: (it has a higher filtration capacity than the frame filter and is suitable for all types of capacities)

Centrifugal filter: (basically it consists of shell, high-speed rotating needle box and moving steel)

Frame filter: (Basically, it consists of a shell, submerged and motionless, box and gear. In this method, the filtration ability is not high and it can be used for the detergent powder production line in a small capacity)

Forced, forced filter: (It is mainly composed of a shell, a stationary sheath box, a lathe with a high rotation speed, and it has a higher filtration efficiency than a centrifugal filter. It is suitable for different capacities)

The main equipment of the washing powder production line

Lower tower

Guard tower

Electric filter

Sprinkler tower

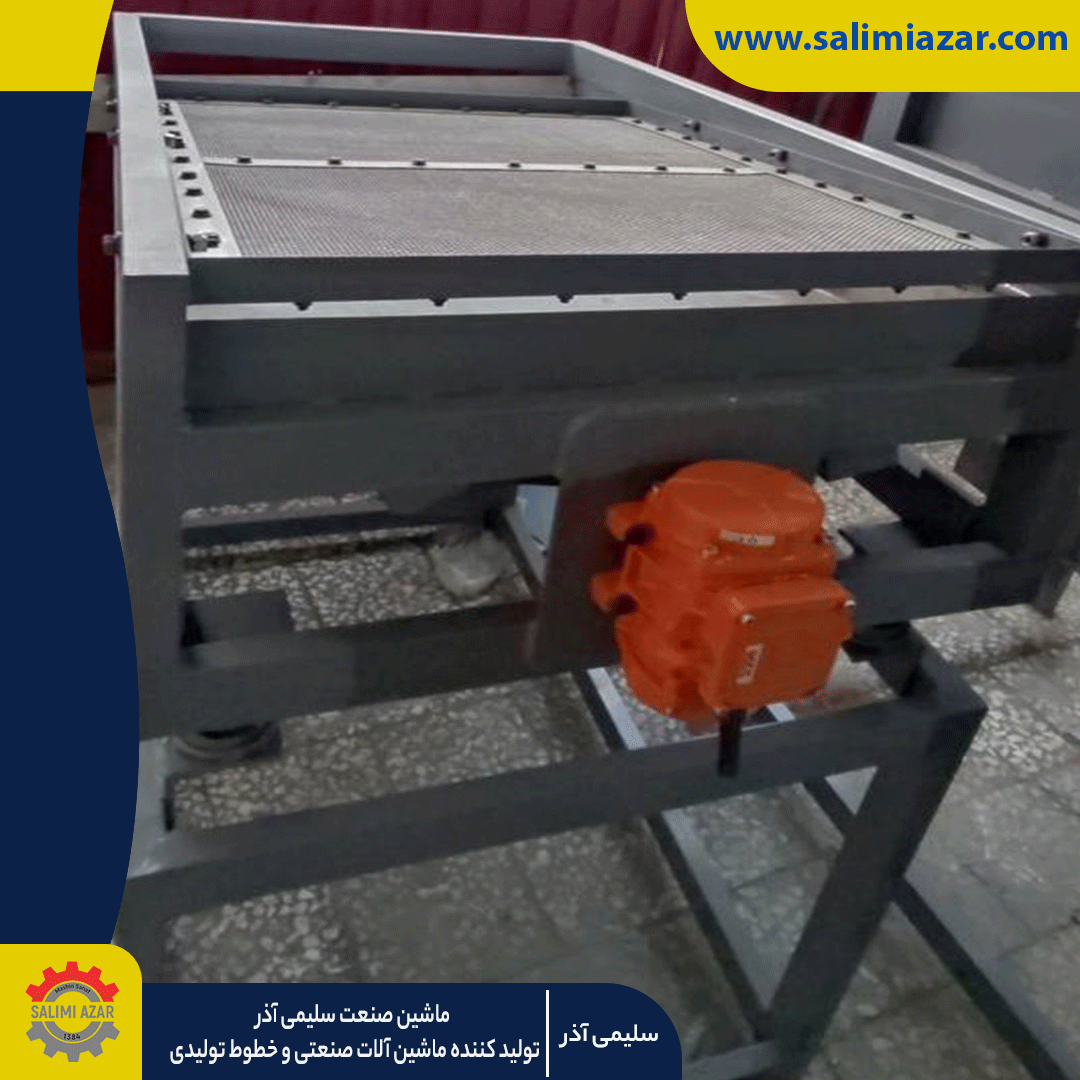

Conveyor belt

Tail gas fan

Separator

Air duct

Conveyor belt

Air fan

Shaky screen

Enzyme bucket

Conveyor belt

Sedimentation

Base powder bucket

Air bag filter

Blue ion box

Vertical elevator

Water weighing funnel

Air feeding funnel

Exhaust spray pump

Exhaust spray tank

Cyclone separator

Hot water circulation pump

Gasoline powder bucket

Lift the sweeper tower

Enzyme electronic scale

Slurry homogenization pump

Send static mixer

Grout spray gun and filter

Blue ion electronic scale

Sodium silicate discharge pump

Sodium silicate delivery pump

Sodium silicate storage tank

Sodium silicate weighing funnel

Pool and waste water recycling pump

Storage tank for washing powder production line

Essential oil transfer pump and device

Sulfonic acid storage tank of the device

Pool and slurry recycling pump and discharge pump

Washing tank for spraying with a hand pump

Essential oil metering pump and production line

Towerless powder production line:

The powder production line without tower is the same as heavy powder (hand powder).

For almost 30 years, manual and machine washing powders have been considered one of the most important and widely used key additives in household purchases. Before modern detergent formulations such as manual and machine powders, soap and sodium carbonate were the main components. The production of detergents and clothes cleaners was known, and the cleaning of clothes mostly depended on mechanical operations.

Some clothes, such as clothes with white colors, are better to be washed by hand. In order to wash these clothes cleanly and accurately, hand washing powders were released to the market. These powders are usually able to remove visible and invisible stains on the clothes. Some of these powders have enzymes such as lipase, amylase, etc., which are very effective in removing all kinds of stains, grease, and dirt from clothes with one wash.

The composition of hand powders should be compatible with the skin of the hand so as not to cause peeling or exfoliation. Usually, this product has a pleasant scent that makes the clothes fragrant.

Manual powder production process:

Shearing and granule shaping: Materials feeding → double screw stirring → shearing and granule

Shaping → discharging → automatic cleaning → automatic reset → automatic conveying → granule shaping → secondary conveying → inspection → sealing → finished products

The powder packaging machine is produced fully automatic and semi-automatic with special designs and different options. In the fully automatic type of this product, there is no human intervention and the operator gives the desired program to the machine through the screen and all the steps are closed. Packing is done automatically. In the semi-automatic model, some packing steps are done manually.

Washing powder production line

Type of production: production of laundry powder / hand powder / dishwashing powder

With light/semi-heavy and heavy density

Capacity of 30 tons in 24 hours

Line automation: fully automatic PLC

The power consumption of the whole line is 100 amperes

The required area is 500 square meters, at least semi-sanitary

Line included

A 2000 liter horizontal double-walled mixer made of 304 stainless steel, equipped with an acid spray system.

A 2000 horizontal mixer of the Stanley 304 Negir type, equipped with an essential oil spray system.

Do not take a six-meter rotating cooling device of stainless steel 304 type

Don’t get a six-meter rotary dryer of stainless steel type 304

A 75,000 gas jet heater

Two gear pumps made of stainless steel 304

Don’t buy a double-decker serand made of 304 stainless steel

A 500 gram semi-automatic bottle filling machine with three nozzles

A single-nozzle bag filling machine equipped with a strip seal and thermal sewing system

Eight conveyor belts of PVC type

Two 1 ton hopper machines

and a four-ton hopper depot

A 500 liter vertical mixer for acid neutralization

and an essential oil tank device.