Salimi Azar industrial machine

- Industrial conveyor belt

- Detergent powder production line

- Packaging filling machine

- Horizontal industrial mixer

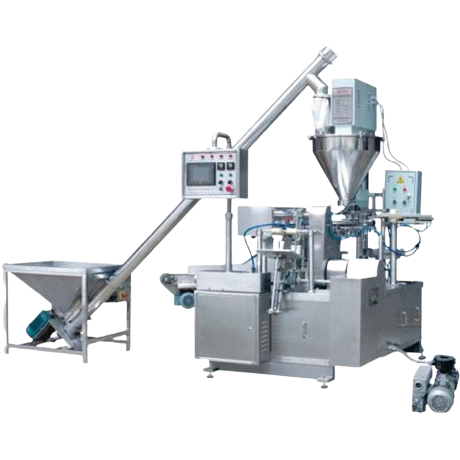

Packaging Filling Machine

Specifications of the packaging filling machine of Salimi Azar company

Capacity 5 tons per hour

Ability to fill 1 to 50 kilos

Number of nozzles 3

Equipped with strip sealing and thermal linear stitching

Maybe many people don’t know what services the filling machines give us! While we are frequently using the products of filling machines in our daily life, it is unimaginable for manufacturers not to use filling machines. All manufacturers of the pharmaceutical, food, cosmetics, and chemical industries use these types of devices to package and present their products to customers, and today, due to the growth of the packaging industry and the position that this industry has found in the world, it is used One of these devices is a necessary and undeniable thing.

With the passage of time and the development of countries, the role of packaging becomes more and more colorful, if manufacturers do not think of unique packaging for their products, they will definitely be removed from the competition scene among similar manufacturers. These devices reduce human error, which is very important in this industry because in this industry all packages must be the same shape and weight, otherwise customers and producers will suffer. The use of various types of packaging devices such as filling devices lead to the reduction of pollution, which in the food, pharmaceutical, and cosmetic industry, it is very important that this pollution be as low as possible and also lead to an increase in work speed and increase Productivity becomes.

Salimi Azar Industry Machine, in cooperation with domestic reliable manufacturers, provides a variety of equipment and filling machines for different industries with the best quality to our dear customers, and 1-year performance guarantee, product authenticity, and after-sales service of these products from the Famco brand for customers. Respected is provided.

How do filling machines work?

These devices measure the dose of the product in different ways, and in some devices, this measurement is completely accurate, and in some devices, it is measured by volume. The industrial filling machine inserts the product into the bottle or envelope with high pressure, before filling the product, the air inside the bottle or envelope must be removed, and in some cases even the bottles are washed. In fact, when the tank pressure is equal to the air in the bottle or envelope, the product will flow. The flow of the product depends on whether the product is solid (granular, powdery) or liquid (thin or thick). In very thick samples, they use a piston cylinder to make the product flow more easily, or sometimes they even heat the product to make it smooth.

Inside the industrial filling machine, there is a sensor that detects envelopes or bottles. Then the product is poured into envelopes or bottles using a funnel or nozzle (the type of this nozzle should be appropriate for the type of product). In powder products, weighing fillers are used, and in the case of liquids, the product is pumped into a bag or bottle by a nozzle. Before filling, it is necessary to remove the air inside the envelope or bottle, to prevent it from moving. This gas discharge is done by modified atmosphere method (MAP) with gas injection. For this, they usually use nitrogen to move the oxygen inside the envelope.

In the example of automatic filling machine, PLC system is usually used. This system is actually a programmable controller, the user can apply the necessary settings in the form of data to the device to display the desired output. The task of this device is to correctly measure and pour the product into the envelope or bottles. Volume packing is done with a unit packing machine and weight packing with a single weighing, two weighing, four weighing packing machine, etc. The price of a volumetric device is more suitable than a weighing device, but the weighing accuracy is much higher in weighing devices.

To choose the right filling machine, you need to have the following information.

What kind of product are you going to fill in the packaging containers?

Be sure to contact our consultants in order to choose the right machine, because if the machine is not suitable for the type of product and the material of your bottles and packaging rolls, your production process will be completely disrupted and you will suffer. So, when consulting, you need to have enough information about your product.

The purpose of this is to offer the most suitable device to buyers both in terms of quality and efficiency and in terms of economy.

What type of operation do you expect from your device (fully automatic, semi-automatic, manual)?

Choosing the type of function of the filling machine depends on the environment in which you intend to use this machine.

What is the production capacity per minute you need? At what level is your production (home, workshop or industrial level)?

For example, for the daily production of less than 2000 pieces, a semi-automatic filling machine will be suitable for you, and there is no need to spend more and get a fully automatic machine.

What mechanism is most suitable for filling your product?

This depends on the state of your product, whether gravity, pump, piston cylinder, volumetric or weighing method is used, etc. The filling mechanism of each device determines the type of filling devices.

To determine the nozzle type of your device, you need to have complete information about the size and appearance of the container and the opening of the container, the angle of the container opening, whether your container is filled from the bottom or not, the type of product, etc.

How to maintain and safety the filling machine

Because these devices are mostly used to fill food, medicine, cosmetics, and chemicals, it is necessary to place the device in a completely hygienic environment and away from any kind of pollution.

If the filling machines are located in wet industrial environments, they need to be washed regularly.

If the device is used to fill chemical and explosive materials, the device must be insured against accidents, and it is also necessary to observe the environmental and electrical safety points.

The body material of your device should be suitable for your product because some products can cause corrosion and rust of the device, which causes pollution and is against the principles of the Food and Drug Organization. To prevent this from happening, you need to use 304 stainless steel for the body of your device.

The best filling machines

Filling machines are among the most important machines in the production and packaging line of food, medicine, etc. These devices have a seemingly simple function and it is enough to use them to transfer manufactured products in different states of solid, gas, liquid, etc. into packaging containers.

In practice, these machines take on a completely complex process, so that they are known as the most versatile packaging machines. Let’s say that in the packaging industry, they always pack different products, which may be poisonous gas or sticky liquids, etc.

Different types of filling machines will face different challenges in the packaging of each of the mentioned materials. Therefore, in buying filling machines, you should be very careful and choose among the best types of these devices. In general, filling machines are divided into the following types:

Weighing devices (weighing)

Bulk and powder devices

Pencil bag machine

Rotary liquid filling machine

Granular filling machine

Linear liquid filling machine

Thick liquid filling machine poisonous gas or sticky liquids, etc.