Salimi Azar industrial machine

- Industrial conveyor belt

- Detergent powder production line

- Packaging filling machine

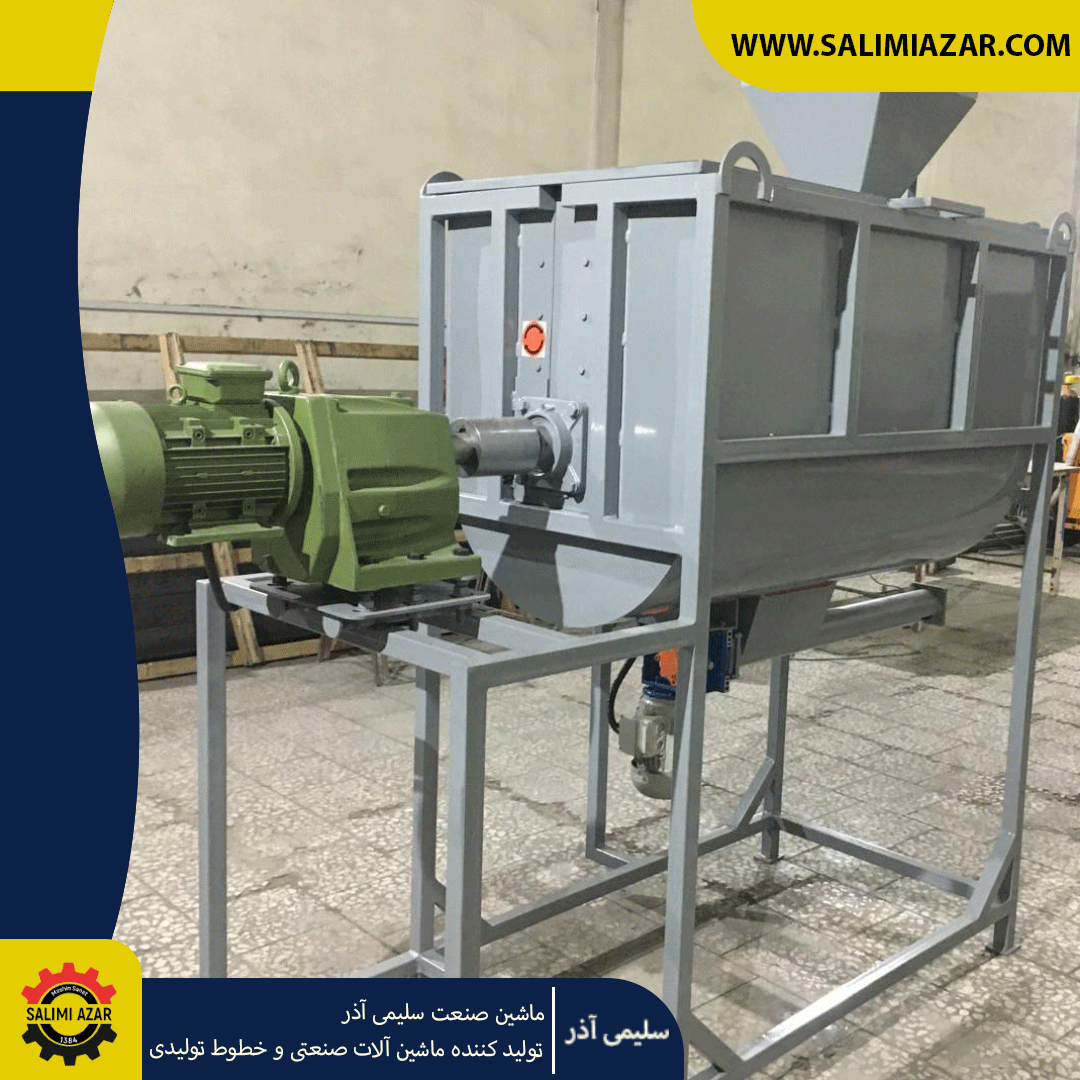

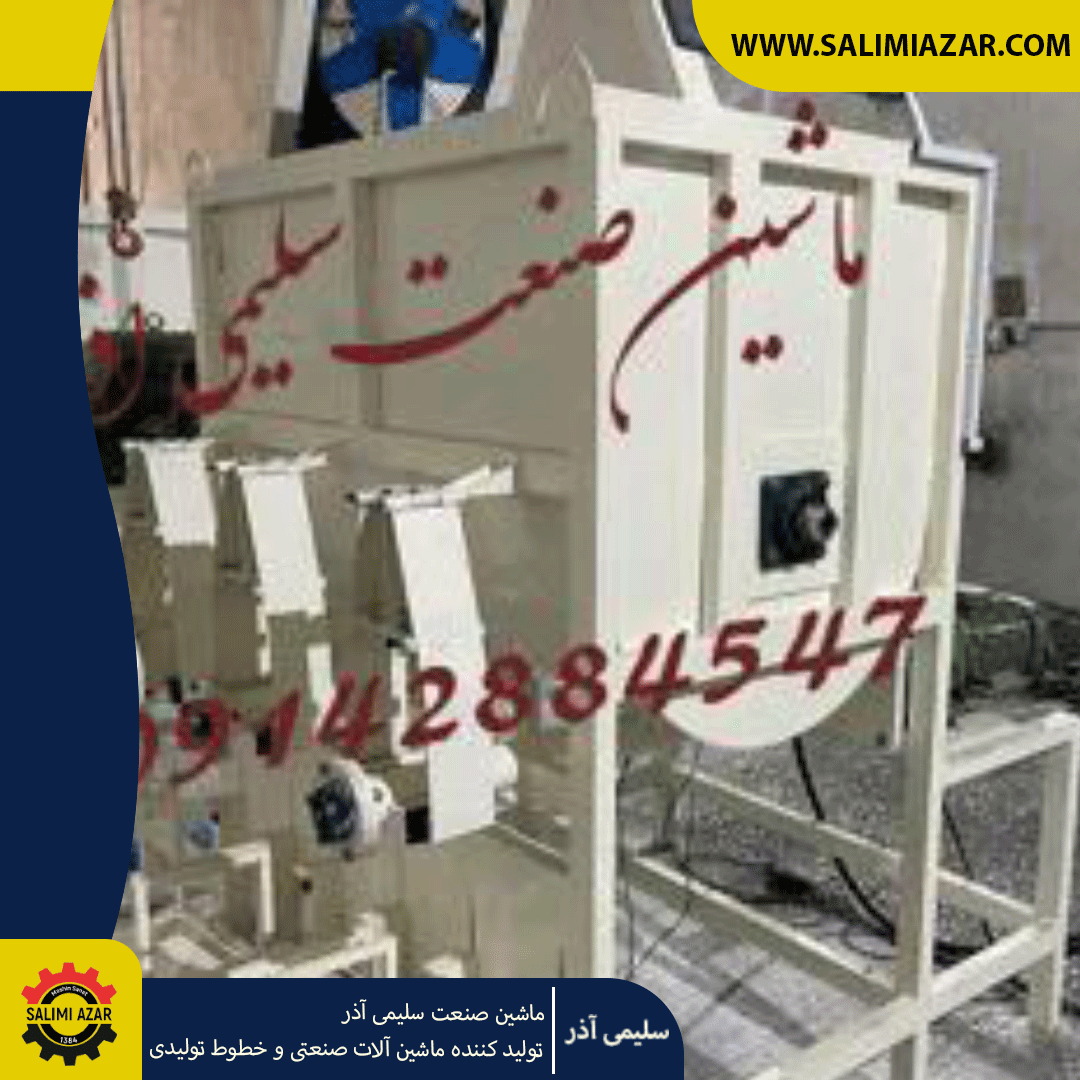

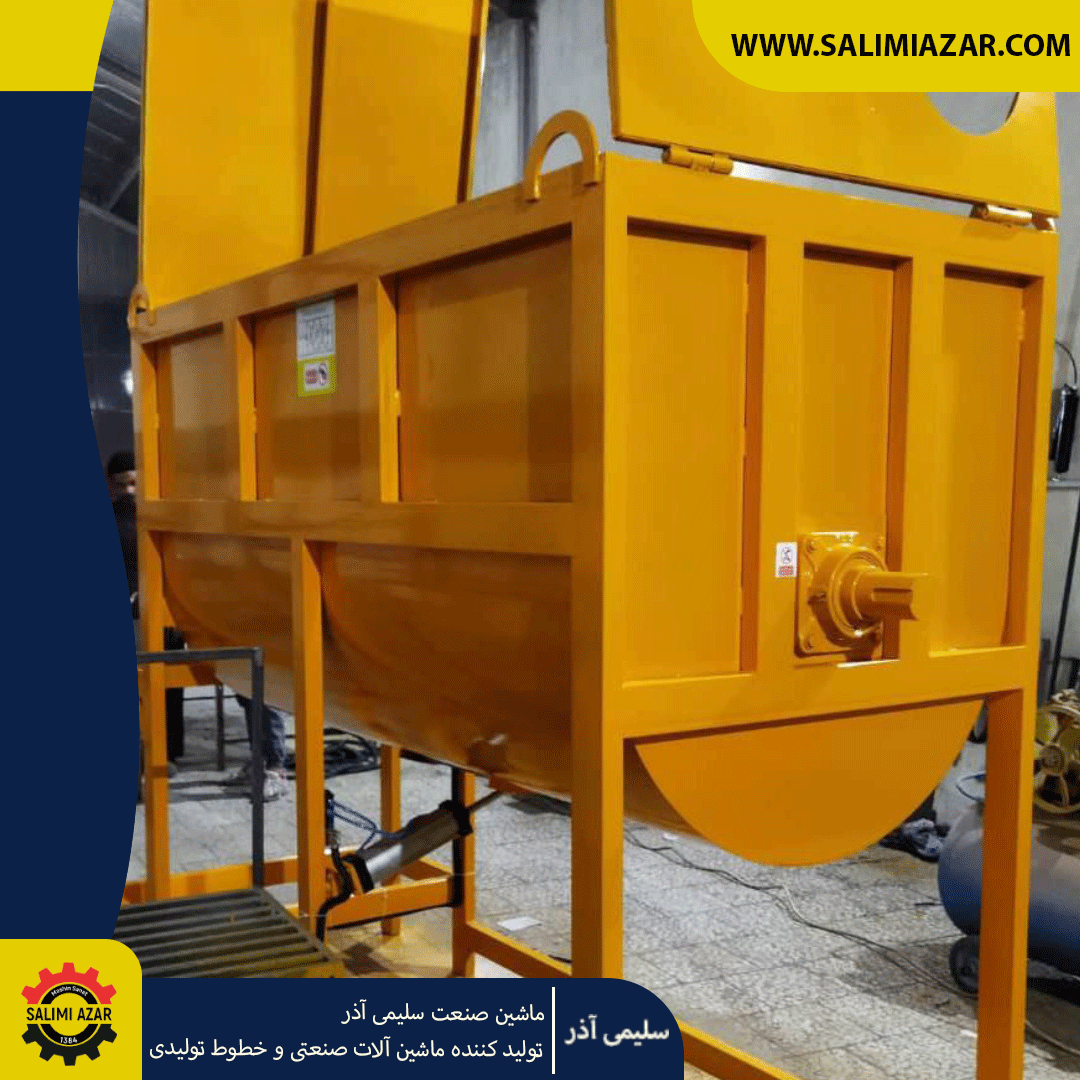

- Horizontal industrial mixer

When talking about a mixer, it should be defined as a set of machines or devices that are used to mix or combine raw materials. Raw materials can be considered in solid-to-solid, solid-to-liquid, and liquid-to-liquid phases in these devices to combine.

Horizontal mixer and its application

1- Uniform mixing of materials: Using a horizontal industrial mixer, materials are mixed uniformly without differences in composition and amount.

2- Saving time: using this device reduces the production time of the product and thus reduces production costs.

3- Cost reduction: By using a horizontal industrial mixer, the need for workers to manually mix materials is eliminated, and as a result, maintenance costs and workers’ salaries are reduced.

4- Improving the quality of the product: using this device, the quality of the product is improved and differences in the composition and amount of materials are avoided.

As a result, the horizontal industrial mixer is an important and vital device in various industries, which improves product quality and reduces production costs.

Horizontal mixers are divided into two categories based on the way the blades move:

1- Horizontal mixer with fixed blades: in this type of mixer, the blades are fixed and the material rotates around them. This type of mixer is used for materials that are difficult to combine, such as paste, ash and metal pellets.

2- Horizontal mixer with moving blades: In this type of mixer, the blades move during mixing. This type of mixer is used for materials that are easily combined such as powder, crystal, granule and liquids.

Also, based on capacity and production capability, horizontal mixers are divided into small and large categories. Small mixers are used for the production of small products and lower work scale, while large mixers are used for the production of large products and high work scale.

Horizontal mixers have different parts that you should pay attention to when buying. In the following, we will learn about the different parts of a horizontal mixer.

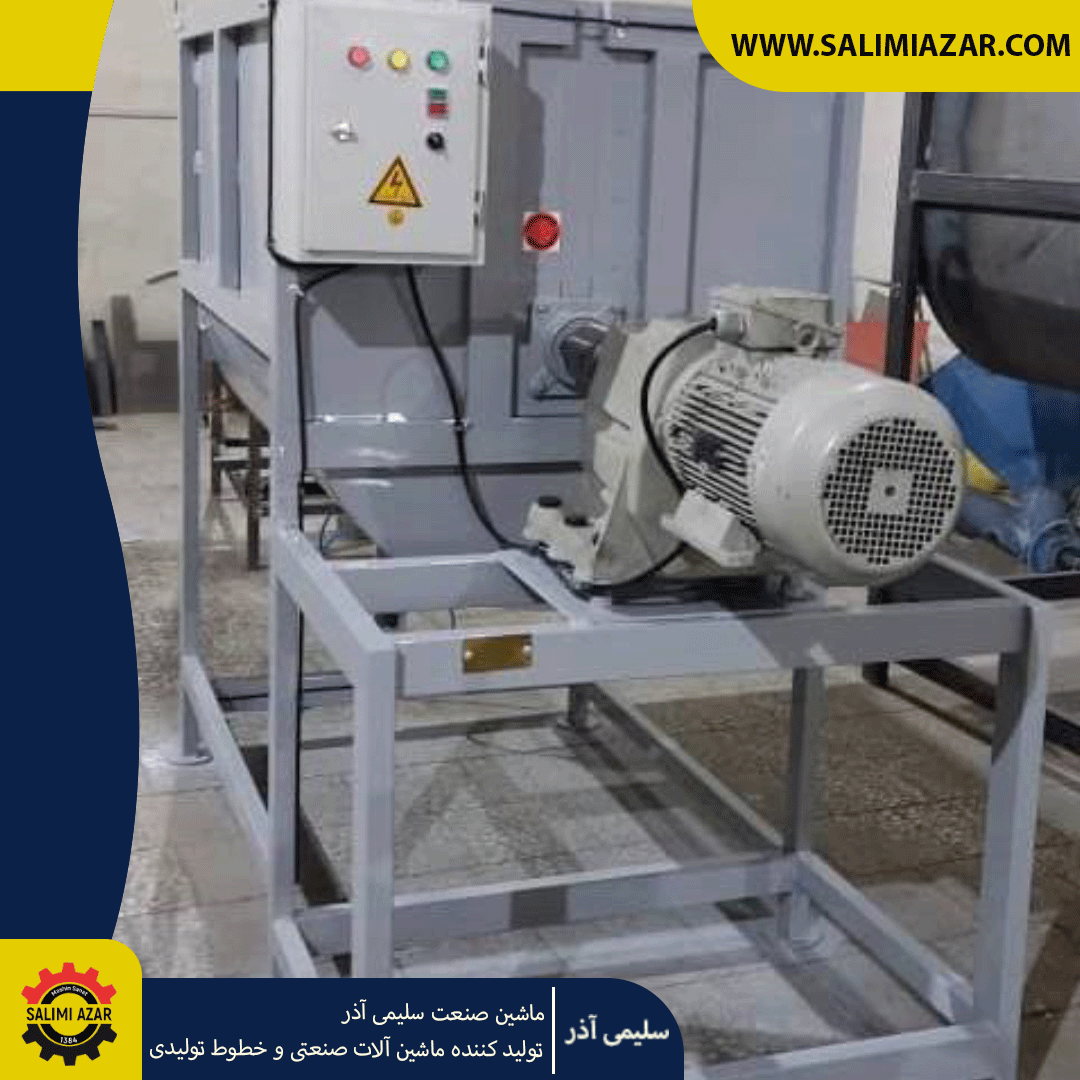

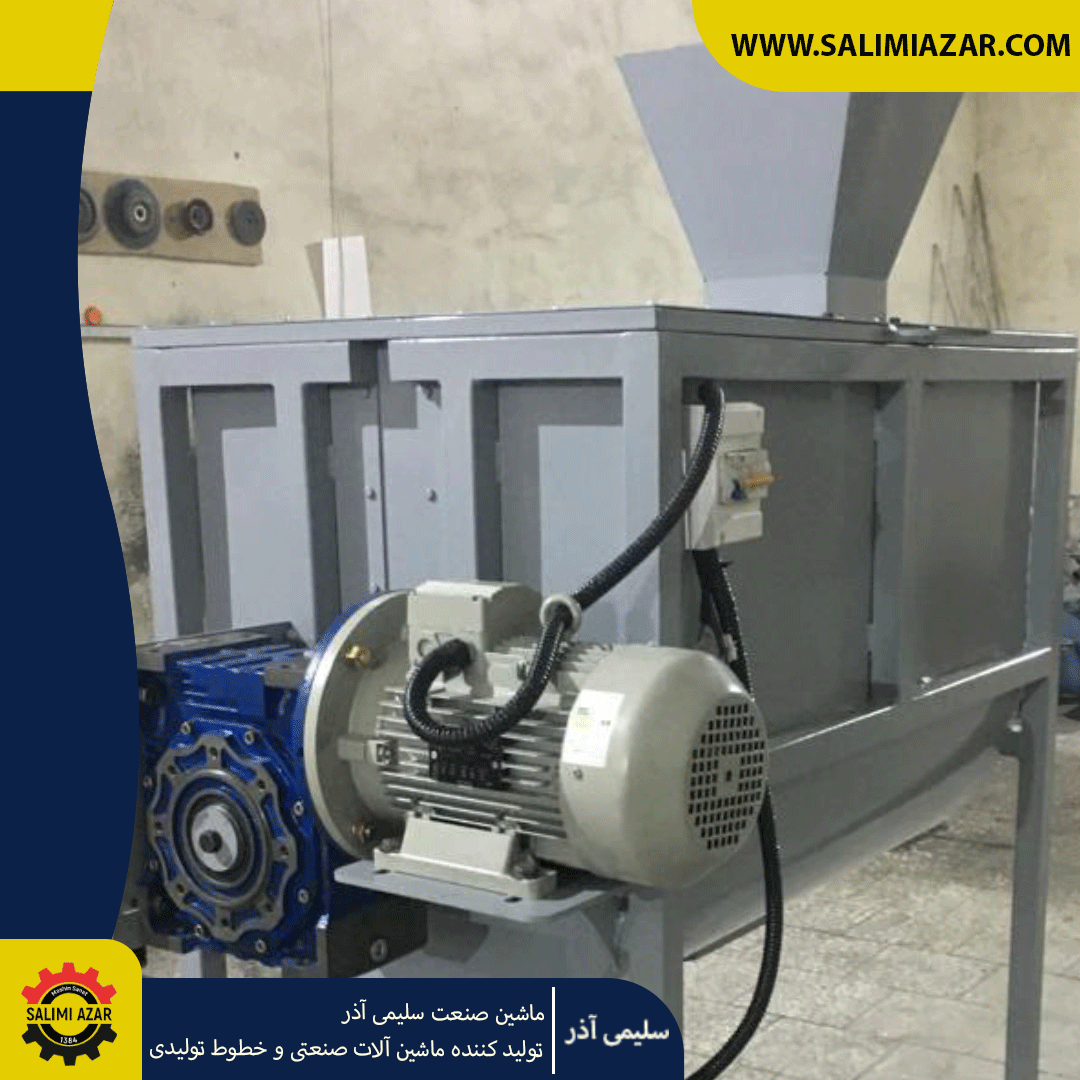

Electro-Motor

The most important part of any mixer device is the electric motor, which can convert electrical energy or electricity into rotary power and operate the mixer. Which electric motor is used on the mixer will have a direct effect on the power and quality of the mixer.

Mixer tank

The tank is the container where you are supposed to put food or powder. These tanks are designed as a regular cylinder or U-shaped.

The important thing to buy a horizontal mixer is to pay attention to the thickness of the tank sheets. In addition to the thickness, you should also pay attention to the welding of different parts of the tank body.

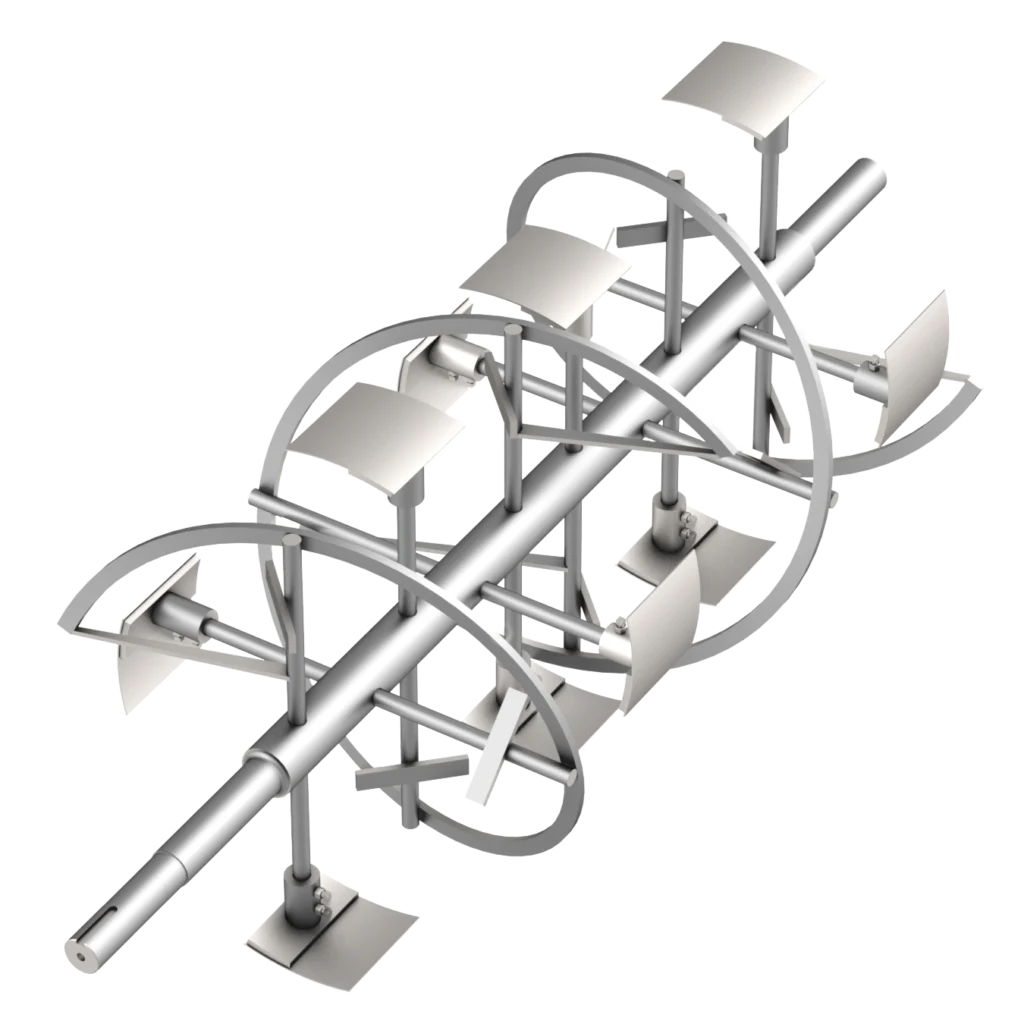

Horizontal mixer axis

Another part of the ribbon blender device or other horizontal mixers is its axis, where the torque produced by the electric motor is transferred to this part. The main axis of the device is usually called shaft or shaft, and mixers are called single shaft or double shaft, depending on whether they have one or two axes.

Pedals or ribbons are the strips of blades that are woven into each other regularly and at a specific angle. In fact, the pedals are welded on the shaft and play the most part in mixing food and powder.

Regarding the minor applications of using horizontal mixers, it should be mentioned its strong bases, which create a special balance on the ground.

In addition to preventing strong vibrations and shocks during mixing, the balance ensures that the ingredients are mixed correctly.

Advantages of horizontal mixer

Horizontal mixers have solid bases. And this structure makes the device maintain its balance when mixing ingredients.

Horizontal mixers have high efficiency both in terms of production and durability.

When one of its components is damaged, it can be easily repaired or replaced.

Maintenance of this device is easy and hassle-free.

As we said above, this device can also be used in chemical and pharmaceutical industries.

Horizontal mixers have the ability and high speed to mix materials.

Horizontal mixers are divided into two categories based on the way the blades move:

1- Horizontal mixer with fixed blades: in this type of mixer, the blades are fixed and the material rotates around them. This type of mixer is used for materials that are difficult to combine, such as paste, ash and metal pellets.

2- Horizontal mixer with moving blades: In this type of mixer, the blades move during mixing. This type of mixer is used for materials that are easily combined such as powder, crystal, granule and liquids.

Also, based on capacity and production capability, horizontal mixers are divided into small and large categories. Small mixers are used for the production of small products and lower work scale, while large mixers are used for the production of large products and high work scale.

Horizontal mixers with a capacity of more than 3,000,000 liters must have 2 shafts due to the low mixing percentage.

Information Table

(Salimi Azar)

price | Mix per minute | Tank metal and central shaft | cassis type: P/Profile N/Stud | Central shaft Filled T | The thickness of the tank sheet | Gearbox K/Ketabi M/ Direct shaft R/ Russian | Dynamo | Device type (capacity) | R |

_ | 18%/M | Steel / Iron | 40*40/P | 50MM/T | 2MM | 90/K | 2.2KW | Horizontal mixer 200L | 1 |

_ | 16%/M | Steel / Iron | 40*40/P | 55MM/T | 2MM | 60/MM | 4 KW | Horizontal mixer 400L | 2 |

_ | 14%/M | Steel / Iron | 40*40/P | 55MM/T | 2MM | 75/MM | 5.5 KW | Horizontal mixer 600 L | 3 |

_ | 14%/M | Steel / Iron | 40*60/P | 60MM/T | 2MM | 75/MM | 5.5 KW | Horizontal mixer 800L | 4 |

_ | 13%/M | Steel / Iron | 40*60/P | 65MM/T | 3MM | 90/MM | 7.5 KW | Horizontal mixer 1000L | 5 |

_ | 10%/M | Steel / Iron | 40*80/P | 75MM/T | 3MM | 90/MM | 11 KW | Horizontal mixer 1500L | 6 |

_ | 9%/M | Steel / Iron | 40*80/P | 80MM/T | 4/MM | 100/MM | 11 KW | Horizontal mixer 2000L | 7 |

_ | 9%/M | Steel / Iron | 40*80/P | 90MM/T | 4MM | 100/MM | 15 KW | Horizontal mixer 2500 | 8 |

_ | 8%/M | Steel / Iron | 10/N | 90MM/T | 4MM | 500/R | 20 KW | Horizontal mixer 3000L | 9 |

_ | 6%/M | Steel / Iron | 10/N 2 | 80MM/T | 5MM | 90/MM 2 | 11 KW 2/S | Horizontal mixer 3500L 2 shaft/ | 10 |

_ | 6%/M | Steel / Iron | 12/N 2 | 90MM/T | 5MM | 100/MM 2 | 11 KW 2/S | Horizontal mixer 4000L2 shaft / | 11 |

_ | 6%/M | Steel / Iron | 12/N 2 | 90MM/T | 5MM | 100/MM 2 | 20/KW/ 2/S | Horizontal mixer 5000L2 shaft/ | 12 |

Types of horizontal mixers:

1-Horizontal single wall mixer

2-Horizontal double wall mixer equipped with cooling and heating system

3- Stainless steel / iron

4- Anti-acid 316 stainless steel

5- Do not use 304 stainless steel