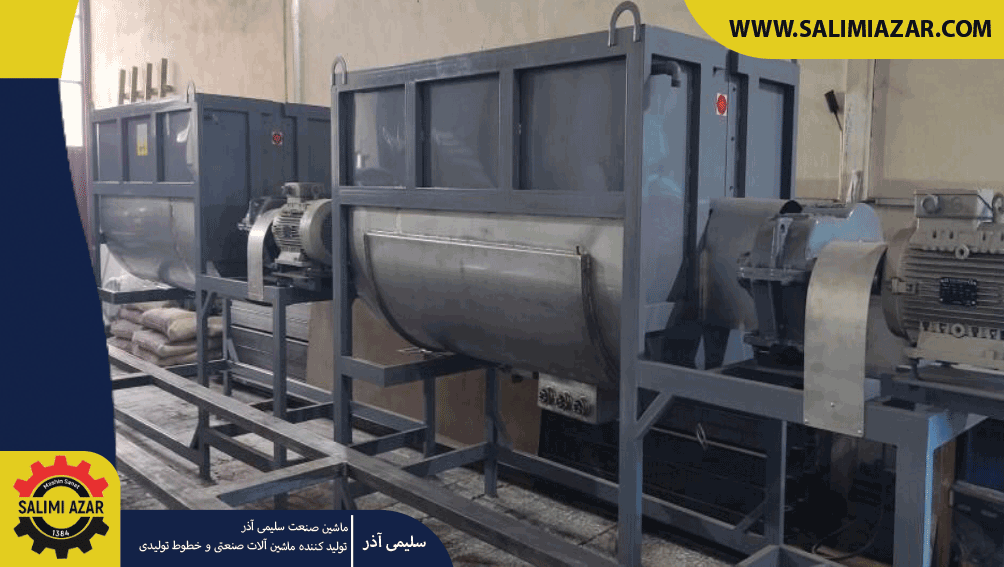

The performance of the double wall powder mixer

First, pour the powder into the tank and keep in mind that for mixing the powder, the order and size of the ingredients are not important and even all the items can be added simultaneously. After that, adjust the temperature of the oil inside the wall using the thermostat inside the electrical panel and start the machine. Now, by directing the inner vanes to the sides and opposite to the center, the outer vanes have caused the powder to move towards the center. With this, the powder mix will be done regularly and uniformly, and the temperature of the tank will absorb the powder. Now, after finishing mixing, open the outlet valve and while it is on, empty the device.

Powder material mixer

The powder materials that can be used in the Ribbon Blender can be a wide range of food industries such as cake powder, fruit powder, flour, sugar, salt and all kinds of spices. Or include chemicals such as sodium bicarbonate, detergent powders and other such substances. Powders also exist in the medical industry, where mixing accuracy is very important.

Granular material mixer

Granular materials are forms of polymer that are produced in petrochemicals as small grains for a variety of applications. To produce and make new materials in various industries, these chemicals are mixed with the combination of other granules or powders and reach the desired material by melting. The best device that can combine the mixing of granules with a high percentage of uniformity will be the powder mixer device.

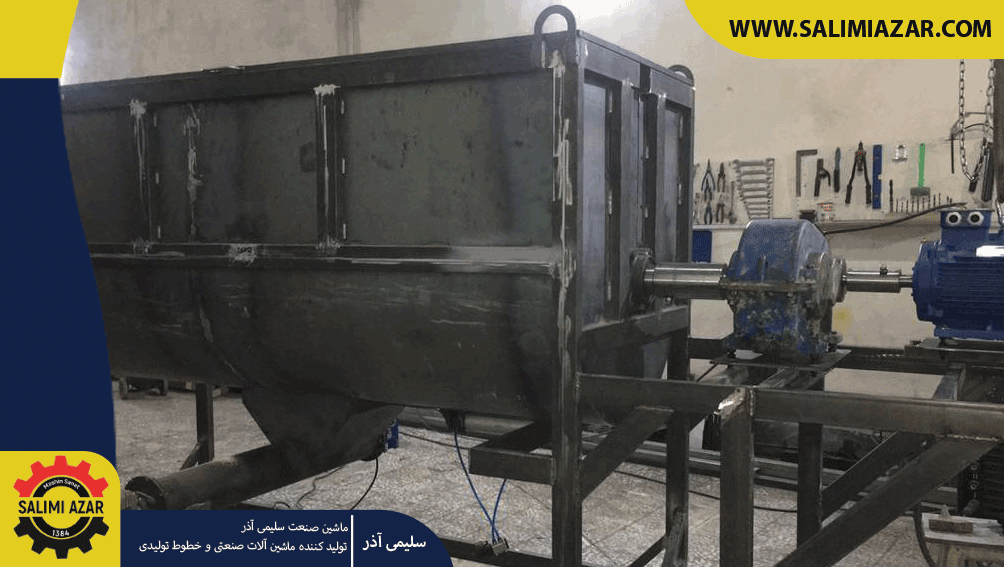

Blender ribbon blade Ribbon Blade

The ribbon blender device or the powder mixer device is equipped with a special blade called Ribbon Blade, which includes two sets of blades with a large and small radius that are connected to a shaft.

These blades are made of stainless steel that can be washed easily. The dimensions and size of the vanes have special calculations to have the best performance and they are designed according to the size of the tank to cover all parts of the powder tank. Another feature of the vanes is its resistance to corrosion, why Many powders and combined essences have acidic properties.